For most classic car owners the absence of modern technology is no great obstacle to their enjoyment. It’s almost the point – the ability to switch off from the modern world and appreciate a vehicle that delivers different sensations unburdened by the complication of modern tech.

That’s not to say modern technology can’t go hand-in-hand with the experience of owning and driving an older vehicle. In some respects, it’s made that ownership experience easier than ever, while design and material advancements have transformed classic car maintenance and modification.

Computer-aided design

Computer-aided design (CAD) certainly isn’t a new technology, having been used in automotive design and manufacturing for decades, but as is often the case, the trickle-down of technology means it’s now accessible to just about anybody, and is becoming as much a part of the classic car world as it has been in new vehicles for half a century.

It ties into several of the other technologies mentioned below – it goes hand-in-hand with 3D printing and laser scanning for instance, but basic CAD software can also be used to quickly draw up accurate models to use as a template for fabrication, or even be sent directly to plasma cutters and other fabrication tools.

There’s an increasing market too for companies that will take your CAD-modelled parts and cut and finish them accurately either as single components or in batches – the latter useful if you’re acting on behalf of a group of owners who need a particular out-of-stock part. At the extreme end of course, the world is your oyster – a dab hand with CAD can create everything from a livery for your race car to all-new bodywork for a restomod project.

3D printing

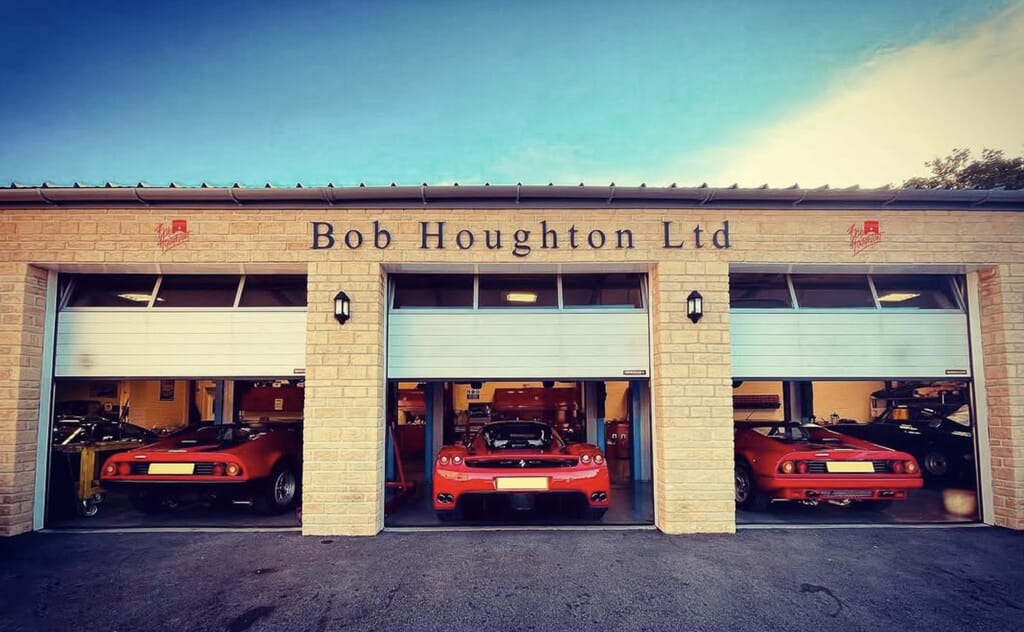

Parts supply is an ongoing worry with many classic and collector vehicles. Car manufacturers are only legally bound to supply parts for older models up to a certain age, and after that you’re essentially at the mercy of the aftermarket or specialists holding stock – or subject to the goodwill of a carmaker like Mercedes, Volkswagen, or Mazda, which remanufacture certain parts for some of their most beloved models.

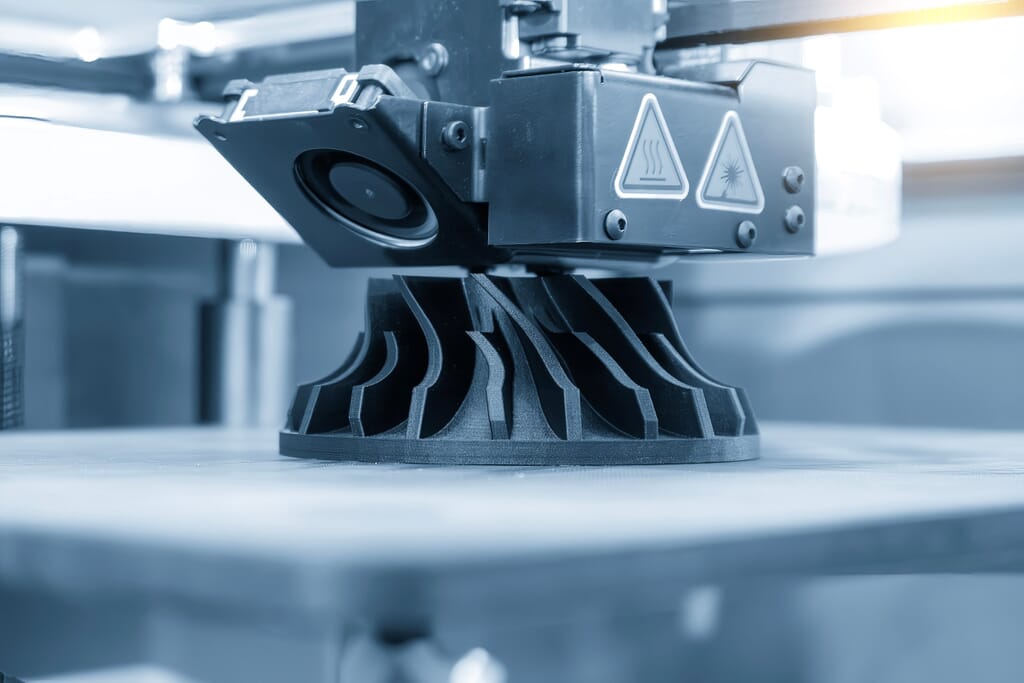

There is another option though and it’s become increasingly accessible in recent years: 3D printing. Often grandly referred to in the industry as ALM, or additive layer manufacturing, it involves slowly building up layers of a particular material to create a whole object based on data fed to the printer by a computer.

Within reason, that material can be almost anything, but as various plastics and metal types are among the options, 3D printing is increasingly popular for creating small batches of car parts that would otherwise be uneconomical to do if reproduced at scale. Home systems are coming down in price – there are dozens available now for well under £1,000 – and are almost perfect for replicating small, fiddly parts such as clips, brackets, plastic trim, blanking plates, and other parts that may have gone out of circulation.

Digital diagnostics

The earliest automotive computer diagnostic technology has been around since at least the 1970s; Volkswagen once boasted that you could take your Super Beetle down to the dealership to be plugged in and generate a printed condition report based on 77 data points.

Things have only become more sophisticated since then. Depending on how old your collector vehicle is, anything from around the mid 1990s onwards will have an OBD2 port, which became the standard for digital diagnostics and be used to gather data on thousands of parameters stored in the car’s computer.

While this once required visiting a dealership to interpret, OBD scanner technology has become so commonplace that you can even do it on your phone, via a Bluetooth sender and an app, while dedicated code reader devices can allow you to interpret and clear codes when your car throws up an issue. Some even allow you to play with certain factory parameters or activate functions only available in other markets – being able to choose how long you’d like the ‘follow-me-home’ lighting to operate for after you turn off the car isn’t hugely useful to most people, but it’s there.

Advanced materials

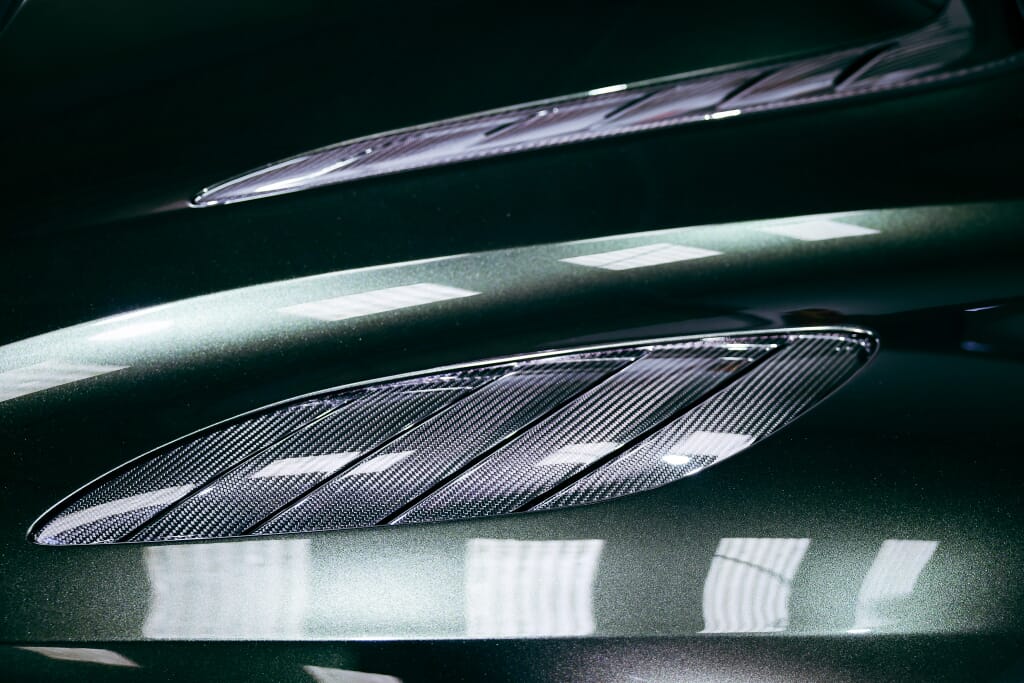

You more or less know what kind of materials you’ll find on a classic car. The chassis will probably be steel, the bodywork steel, aluminium or fibreglass. Engines and their components will be iron, steel, and various alloys, interiors a mixture of plastics, leathers, fabrics and finishing materials like wood or metal. There’s some rubber and glass in there too.

Except you no longer need to stop there, as advances in materials technologies, and the lower cost of certain previously rare materials driven by manufacturing improvements and their sheer ubiquity, mean that depending on your car, there may be more options open to you than in the past.

The most obvious example of this can be found at some of the high-end automotive restomod workshops, which can recreate every panel of a car in carbon fibre. Advanced materials don’t stop there however, with titanium increasingly used for certain engine and exhaust components, light-weight 3D-printed metal and plastic parts replacing heavier milled and cast metals, and recycled materials increasingly used as a substitute for polymer-based ones.

3D/laser scanning

Being able to design and fabricate parts from scratch, or use 3D printing to build a component from the ground up is one thing, but ensuring those parts will fit where they’re supposed to is quite another. Sometimes it’s a case of trial and error, test-fitting components into a busy engine bay or interior space, before removing them again and iterating before they fit, but in recent years, 3D scanning has given restorers and car builders another tool for the job.

Using a handheld laser scanning device, it’s now possible to build a 3D model of just about any component or space on a car. Whether used for creating 3D replicas of components to be 3D printed later, or mapping an engine bay from which precise measurements can be drawn to fit new components, assess the space for engine swaps, or generate data for repair panels, the technology has dozens of potential uses.

While not cheap – the type of scanners you’d use for most automotive jobs are upwards of £1,000, and you’ve got software to consider on top of that – the potential benefits are huge, whether restoring a car from scratch or being able to generate accurate data on parts where original technical drawings may not exist.

Engine management

A huge advance in the usability of a certain generation of older cars has been the rise in fully mappable engine management. Computer-controlled ignition and fuelling brought driveability benefits when it was introduced, but earlier systems are still pretty rudimentary by modern standards and often at the mercy of ageing circuit boards or vacuum lines for information and actuation of certain functions.

While many people think of aftermarket ECUs as being a way of boosting power, their modern benefits are manifold. A car’s ignition and fuelling maps can now be far more precisely controlled and far more adaptable to different driving conditions, especially when combined with other more recent technology such as coil-on-plug ignition.

As well as driveability, these systems can also improve safety, pulling timing or fuel when problems are detected, or cutting in fans at lower temperatures to improve cooling. There’s the opportunity to play too, with some allowing for programmable traction control, flat-shifting, or launch control modes. It’s not the preserve of ECU-era cars either – swap your older car’s carburettors for EFI, and modern engine management comes into play here too.

Oil analysis

Today’s oils are impressively resilient even in the highest-performance vehicles, and can last far longer than the pure mineral oils of old without losing their lubricating properties. What you might not know is that beyond looking what colour your oil is as it drains from the sump, your engine’s lubricant can tell you a great deal about the condition of the engine itself.

Oil analysis has become increasingly popular in recent years. The basic idea is that you send off a sample of your oil at each change to a company that runs both light-based and chemical tests to assess both the oil’s condition, and to see what particles are suspended in the oil.

Results will often include measurements on soot particles from combustion, unburned fuel, coolant, metals (through wear and tear of engine components), and dirt. Excessive quantities of any of these could highlight a problem thousands of miles before other symptoms appear, and the company may be able to recommend more regular changes. Hand-held testing devices are also available for more regular home checks, though naturally these won’t give you a detailed breakdown like a professional testing company can.

Non-invasive body treatments

Returning a car to bare metal or removing decades of grease and rust from a chassis or components can be a pretty brutal process, often involving harsh chemicals that are unpleasant to work with, or blasting that can potentially damage the surface of whatever it is you’re working on.

Two relatively recent technologies offer a less invasive way of cleaning up rust and contaminants however. The first is dry ice blasting, which uses dry ice – solid particles of carbon dioxide – fired at the underside of a vehicle, or individual components, to break away dirt and corrosion on the surface, and even blast away underseal, without damaging the metal beneath – and as it’s adjustable for strength, it can even be used in certain painted areas or on more delicate surfaces.

More spectacular but similarly effective is laser rust removal. You wouldn’t want to use this on any painted surface (unless the intent was to remove that paint) but it’s very effective at cleaning surface rust, using a powerful, pulsing laser beam that evaporates rust on a metal surface while leaving the metal intact.

Windrush Car Storage brings decades of classic car expertise to help you make informed decisions about integrating new technologies. We can help classic car owners navigate these options, connecting you with trusted specialists and providing guidance on which modern technologies make sense for your specific project. Please get in touch with our team today if you’re looking for car storage for your classic car.